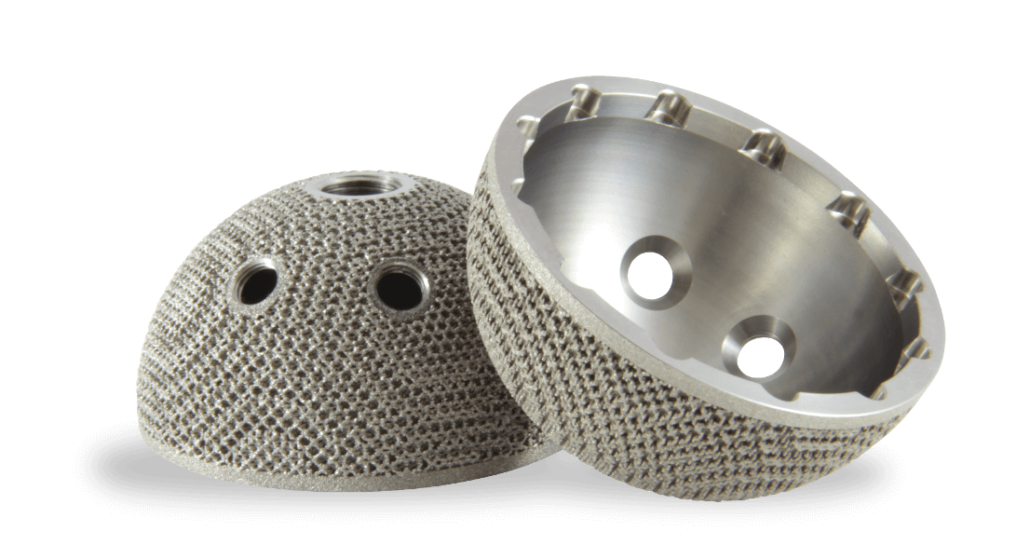

Technology principle

How does Laser Beam Powder Bed Fusion work?

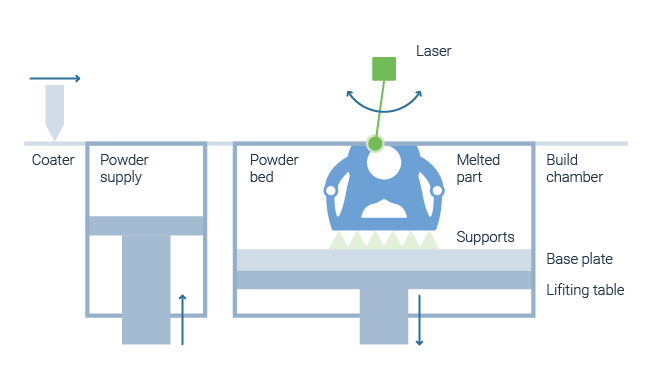

Laser Beam Powder Bed Fusion (LB-PBF) is based on melting of a powder feedstock by exposure with laser radiation. The powder material is applied by a leveling system in a predefined layer thickness to a substrate plate fixed on the build platform. The leveling system can be a blade, brush or roller that applies a predefined amount of powder from a reservoir and spreads it on the substrate plate. Alternatively, the powder container itself is moved across the substrate plate and distributes the powder evenly.

The energy for bonding the powder particles is provided by a laser. The laser beam is directed on the powder bed so that it selectively melts the powder. Machine development started with one laser source and optic, today many production systems use multiple laser to increase productivity. For guiding the laser beam, often a mirror deflection system is used. Furthermore, machine systems exist in which the laser is moved via a gantry with multiple axes. These solutions promise to be especially cost-efficient.

When the exposure process is completed, the build platform is lowered by the amount of the layer thickness and the next powder layer is applied. When re-exposing the next layer, it fuses with the previously generated layer. The process described is repeated until the entire component geometry is generated. The unexposed powder remains loose and can be recycled.

Because of the strong reaction tendency of metallic powders, the process takes place in protective atmosphere. Before starting the process, the build chamber is purged typically with argon or nitrogen, until an oxygen content of less than 0.1 % is reached. Alternatively, machines exist in which the process takes place under vacuum.

The most important process parameters are the laser power, scanning velocity, the diameter of the laser beam focus and the scan strategy, that defines the pattern in which the powder is exposed. Optimal parameters differ depending on the metal alloy and the powder characteristics.