Metal FDM

9. January 2025 in Metal, Technology /by Adm@amp_01Technology deep dive

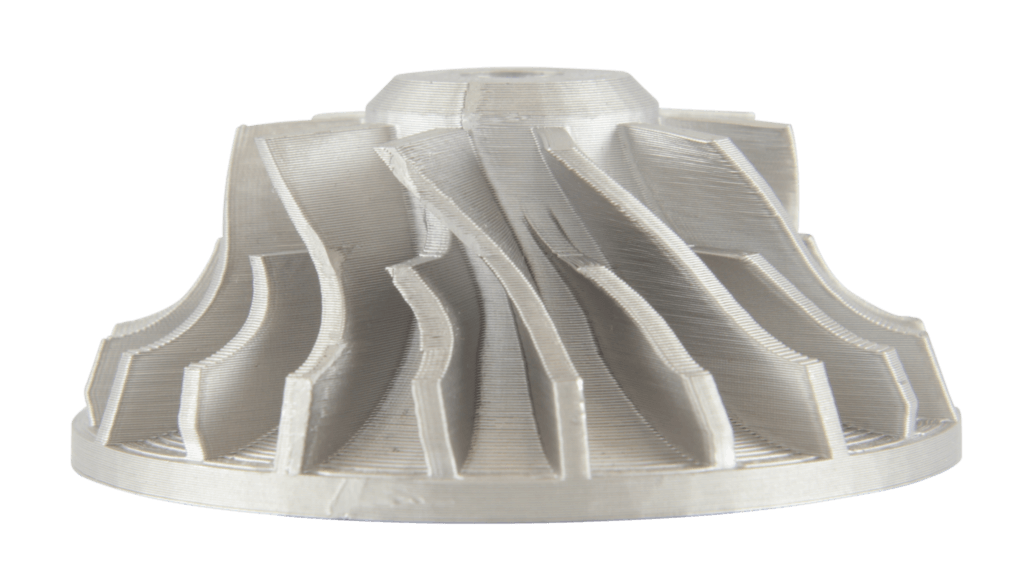

Metal FDM - low batch metal printing

Learn the background and state of the art of metal FDM. The process is based on the widely known polymer technology called Fused Deposition Modeling also known as FDM. Several variants are known and many new suppliers are currently going to market with either metal FDM system technology or feedstock.

What you will find in this report section

You are not logged in or you do not have a subscription to the AMPOWER Report 2023.

To access the full report content please login or purchase a plan.

Click here for a market report summary.