Metal AM market size 2025

14. March 2025 in 2025, Metal Market /by Maximilian MunschMarket size

What is the metal Additive Manufacturing market size?

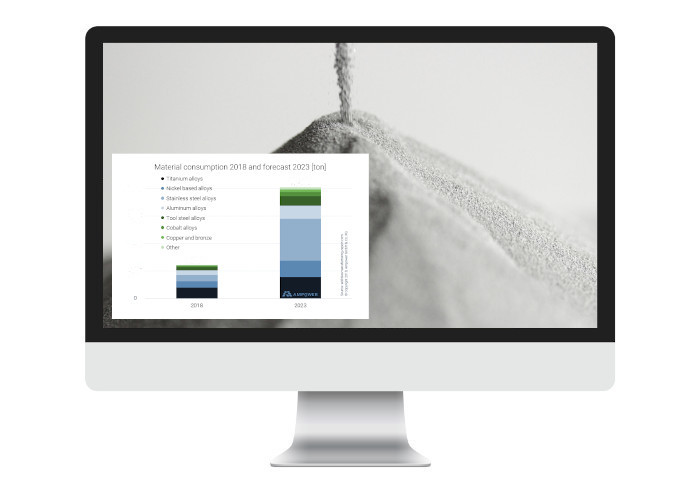

Additive Manufacturing experiences massive growth and is considered to be one of the key technologies on the path of digitalization and industry 4.0. The ability of manufacturing parts directly from a CAD file is creating high expectations in the market. Nevertheless, the metal Additive Manufacturing market size is still a niche compared to other manufacturing technologies. Currently, the market is valued at about EUR 3.5 billion with a projected growth in the double digit range.

What you will find in this report section

You are not logged in or you do not have a subscription to the AMPOWER Report 2025.

To access the full report content please login or purchase a plan.

Click here for a market report summary.