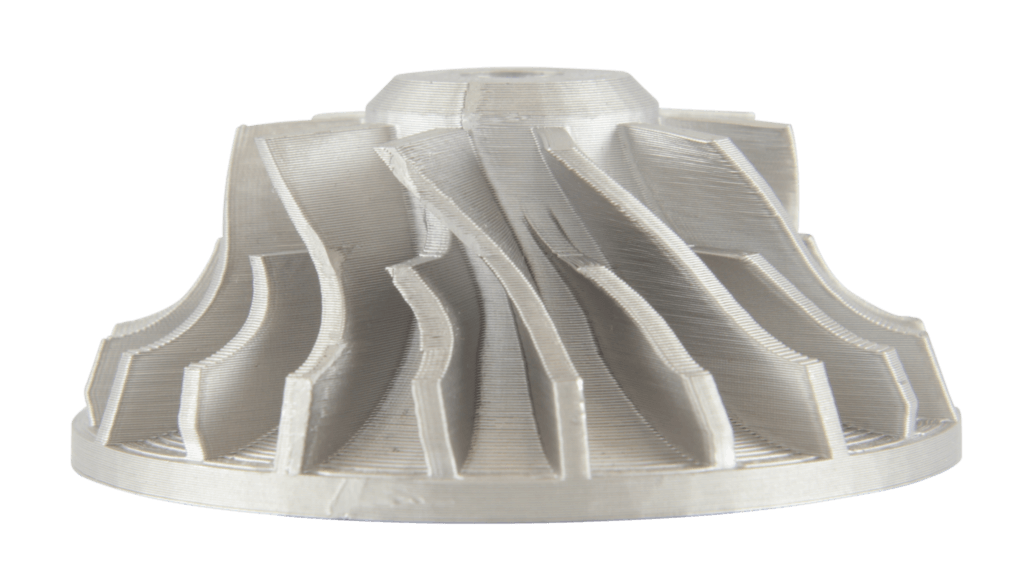

Laser Beam Powder Bed Fusion

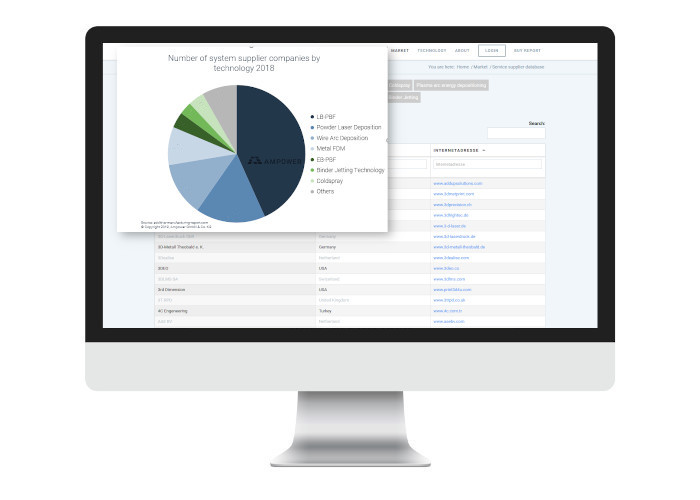

LB-PBF or laser beam powder bed fusion, also known as selective laser melting (SLM), is the most known metal Additive Manufacturing technology. With an installed base of over 7,000 systems, the technology is now wide spread with many public applications in production. This report section gives a broad overview of the state of the art of laser beam powder bed fusion.