Welcome to Singapore, a global exemplar of efficiency, cleanliness, and cultural harmony—a nexus where diversity is fundamental to business success. As one steps onto the grounds of Changi International Airport, the transformative touch of Additive Manufacturing (AM) subtly unveils itself. From Tiffany’s resplendent 3D-printed store façade, crafted from recycled materials, to the ethereal AirMesh Pavilion at Gardens by the Bay, and the heartening tale of the Great Hornbill at Bird Paradise receiving a 3D-printed prosthesis—these moments herald Singapore’s foray into AM, propelling it into a future poised for brilliance.

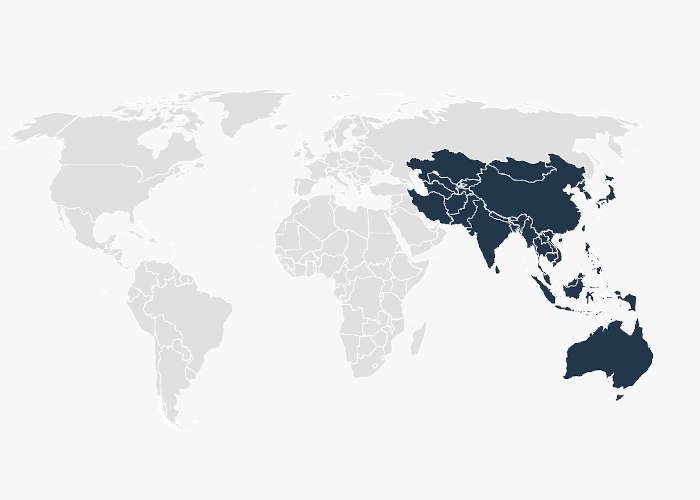

Singapore’s ecosystem has undergone a rapid evolution over the past decade. The amalgamation of sustainable growth, technological advancement, and the cultivation of a skilled workforce attuned to the intricacies of AM defines Singapore’s commitment to a future where 3D printing plays a pivotal role in the economic and technological landscape. At the intersection of technology, research, and industry, Singapore strategically positions itself as a hub for AM excellence. Dynamic partnerships involving key government agencies, such as the Economic Development Board Singapore (EDB), Enterprise Singapore (ESG), National Research Foundation (NRF), and the National Additive Manufacturing Innovation Cluster (NAMIC), alongside esteemed research institutions like the National University of Singapore (NUS), Nanyang Technological University (NTU) and SUTD, form the bedrock of this flourishing ecosystem.

Central to Singapore’s commitment is the synergy fostered through robust public-private partnerships. The National Additive Manufacturing Innovation Cluster (NAMIC), established in 2017, brings together government agencies, research institutions, and industry leaders to collectively propel the adoption and acceleration of additive manufacturing technologies. NAMIC’s Annual Additive Manufacturing Week held in September 2023, is a showcase of capabilities and innovations driving AM, and its Global Additive Manufacturing Summit serves as bastions of thought leadership. The summit witnessed the signing of significant MOUs, including the establishment of Pelagus 3D, a joint venture between THYSSENKRUPP and WILHELMSEN, positioning it as the largest on-demand digital manufacturing partner. The Start Up Innovation forum, a platform to nurture and propel AM solutions to the next level was held for the 4th year attracting global interests.

Initiatives such as the Advanced Remanufacturing and Technology Centre (ARTC), a public-private partnership between A*STAR and industry leaders like ROLLS-ROYCE, P&G, HYUNDAI, SIEMENS, VOESTALPINE, and HALLIBURTON, underscore Singapore’s commitment to addressing manufacturing challenges collectively. The recent addition of German motion technology company SCHAEFFLER in 2024 further enhances this collaborative synergy.

Multinational companies (MNCs) in Singapore have embraced AM. Siemens has invested in a large Advanced Manufacturing Transformation Centre (AMTC) as a show case for various OEMS and skills upgrading. GE Additive has invested in a centre of excellence. GE Aviation Singapore offers metal AM for engine component repair and is the first facility worldwide that has been approved to use metal AM for commercial jet engine component repairs. Airbus is launching its Sustainable Innovation Hub with AM as a feature.

Over 200 further companies leverage 3D printing technologies for prototyping, small-batch production, and advanced manufacturing. Enterprise Singapore (ESG) plays a pivotal role in empowering SMEs with AM technology. Collaborations continue to sprout in various sectors, exemplified by the Maritime Port Authority and NAMIC launching the Joint Industry Program Phase 3 in 2023 to drive AM adoption and innovation for the maritime sectors with strategic consortia of ecosystem collaborators.

Singapore’s advanced manufacturing vision acknowledges the transformative potential of emerging technologies like artificial intelligence, robotics, additive manufacturing, and advanced materials. Centres of excellence for Additive Manufacturing in various industry verticals, such as the ASTM Centre of Excellence, JOHNSON & JOHNSON – National University Hospital 3DP Point of Care lab, and HP-NTU Corporate Lab, are testaments to the growing investments by MNCs in Singapore. Recent collaborations, such as NTU and Singapore General Hospital’s commitment to a joint R&D lab in AM, signify the exploration of 3D printing for regenerative medicine and the development of 3D prosthetic and orthotic devices.