- AMPOWER Report

- AM Application Catalogue

- Applications

- Leak repair clamp

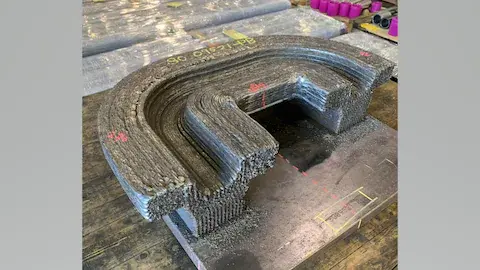

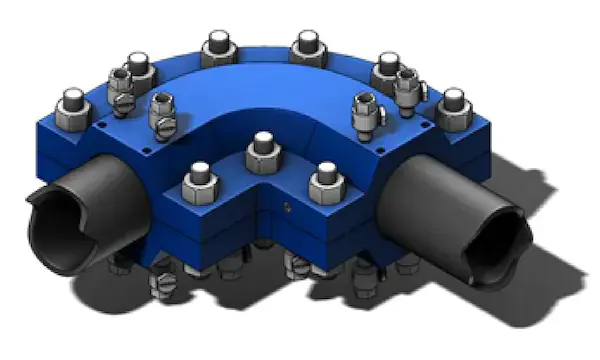

Leak repair clamp

-

User: Shell

-

Industry: Oil & Gas

-

Material: Steel

-

Technology: Wire Arc Additive Manufaturing

-

Classification: Non qualified end part

Shell has successfully installed its first 3D printed WAAM (Wire Arc Additive Manufacturing) leak repair clamp in service. Traditionally, manufacturing a simple clamp would take between three to five days. However, if the clamp was complex, it could take up to four weeks or even more, and availability of such essential equipment becomes critical for maximizing operations. With WAAM technology, manufacturers can produce parts with intricate geometries and outperform other conventional techniques like casting or forging. In this instance, the 3D printed clamp underwent a burst test, which it passed successfully, achieving 142.4 bar.

Courtesy to: Shell