Technical fields for start-ups in Additive Manufacturing

Start-ups from incremental improvements to groundbreaking innovations

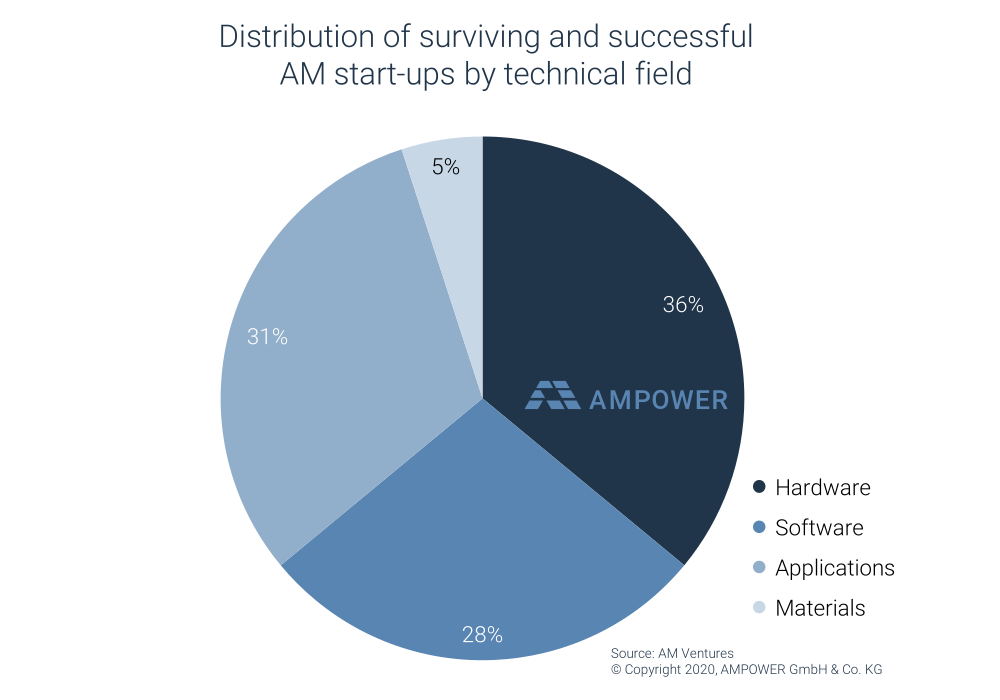

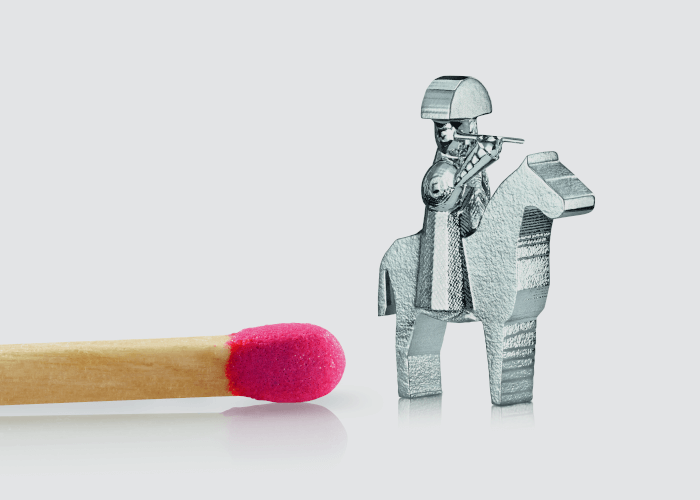

Start-ups are bound to create added value among the existing ecosystem to survive and strive. In AM, this ultimately leads to reducing cost, increasing quality or enable reduction of manufacturing time for their customers. The Additive Manufacturing start-up ecosystem can be clustered into four fields:

- Hardware, such as printing systems and post processing technologies

- Software, from simulation and data preparation to MES and quality management

- Applications, utilizing existing AM technologies for new products

- Materials

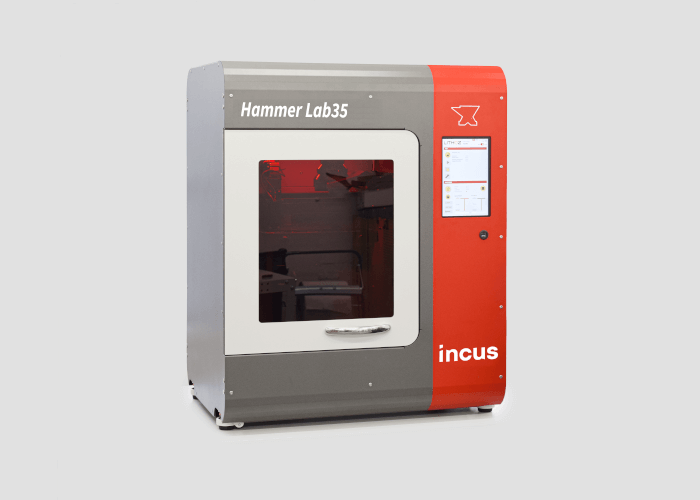

Start-ups focusing on hardware solutions are most prominent, especially when developing completely new AM technologies. More than half of the known metal Additive Manufacturing technologies are driven by start-ups such as DIGITAL ALLOYS, TRITONE, INCUS, LITHOZ, VELO3D or SPEE3D. Hardware developments are known to be investment intensive and high risk, since in many cases first earnings take several years.

Software development might have a lower entry barrier due to reduced investments, but faces a highly competitive and dynamic market environment. Typically the start-up involved in software often targets a rather quick buy-out by a large CAD/CAM supplier, since the introduction of a new and stand-alone software solution in established digital environments of enterprises is challenging. Examples for software start-ups are 3YOURMIND and ADDITIVE WORKS.

Companies like URBAN ALPS or CONFLUX TECHNOLOGY are focusing on developing new applications using the unique properties of AM technologies. The resulting product must serve a need only satisfiable by the use of AM.

The last group focuses on developing or optimizing materials for Additive Manufacturing. Companies like 6K, METALYSIS, ELEMENTUM 3D and MOLYWORKS target to develop cost efficient feedstock production, recycling or creating unique alloys. Start-up HEADMADE MATERIALS develops a solution to enable an existing polymer manufacturing technology to be utilized for printing metal green parts.

![20 regional distribution of analyzed metal and polymer am start-ups by technical field 2019 [share of entities]](https://additive-manufacturing-report.com/wp-content/uploads/2020/04/20-regional-distribution-of-analyzed-metal-and-polymer-am-start-ups-by-technical-field-2019-share-of-entities.png)