Polymer Additive Manufacturing history

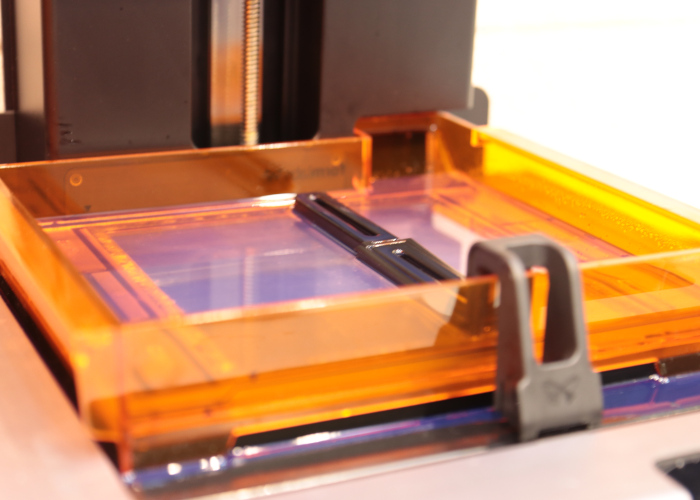

First experimental set-ups and early machine concept developments in Additive Manufacturing go back to the 60s and 70s of the 20th century. The Additive Manufacturing market landscape has changed over the last decades. It all started with the invention of the Stereolithography process by Charles Hull. This Invention can be declared as the point of origin for the polymer AM market as well as the entire AM market.